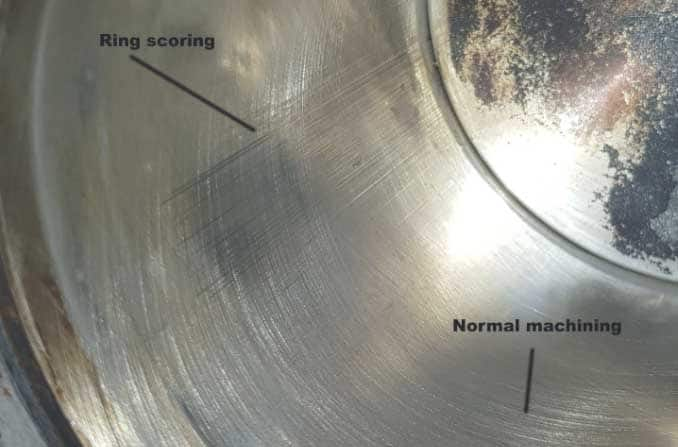

Above 20 percent loss and it may be time for a teardown and rebuild. If you have lost ring seal then you will make less power go slower.

Cylinder Leak Down Test To Detect Oil Leakage Motor Vehicle

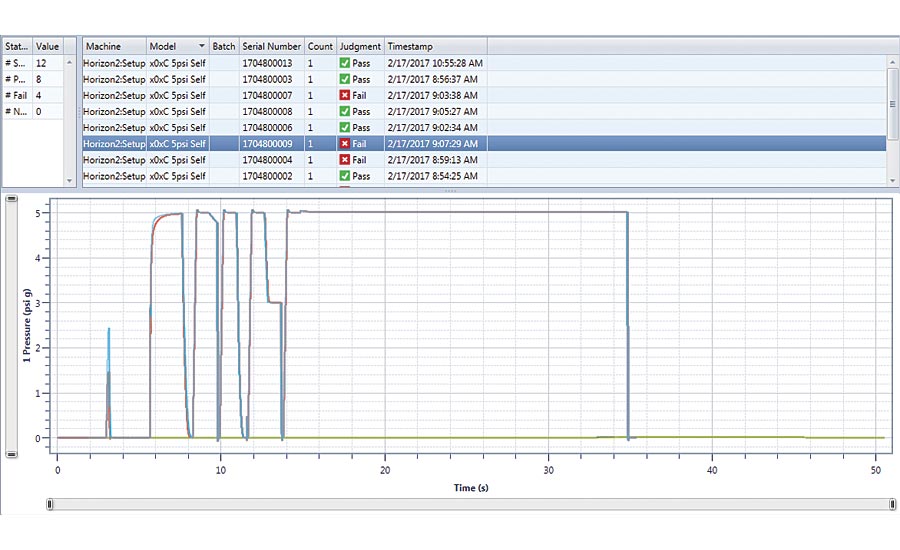

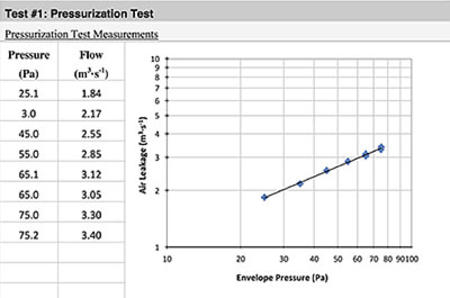

Acceptable leak down test results. Measuring crankcase blowby at 7000 rpm under load will be much more accurate. In simplified terms if air is pumped into the cylinder at 100 psi and the gauge reads 97 psi then the leak down percentage is 3. It deals with how well the cylinder is sealing and nothing else. The procedure is similar to a compression test to a point. To get back to your question as long as the cranking compression is relatively equal i wouldnt worry much about the 40 percent leakage. The intake valve leads to the intake manifold and the exhaust valve leads to the exhaust tailpipe.

To perform the test you must first remove the spark plug on the cylinder youre going to test. A 91 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level 9x1471323. Perform a cylinder leakage test by injecting regulated shop air into the cylinder heads spark plug hole then visually searching and listening for a leak. Engine compression atmospheric pressure at sea level is approximately 147 psi. You would want to check the vac pump to make sure no vanes have stuck for starters. Like joe said 15 20 doesnt mean much.

No engine will have perfect sealing with 0 percent loss. The cylinder leak down test reading is expressed in a percentage. An engine between 10 and 20 percent can still run ok but itll be time to keep an eye or ear on things. I might break out my leak down tester after i find a cylinder with low compression or i might start with a leak down tester when i suspect a mechanical problem with the engine. The valves rings and head gasket seal the combustion chamber. So the great thing about the cylinder leak down test is that.

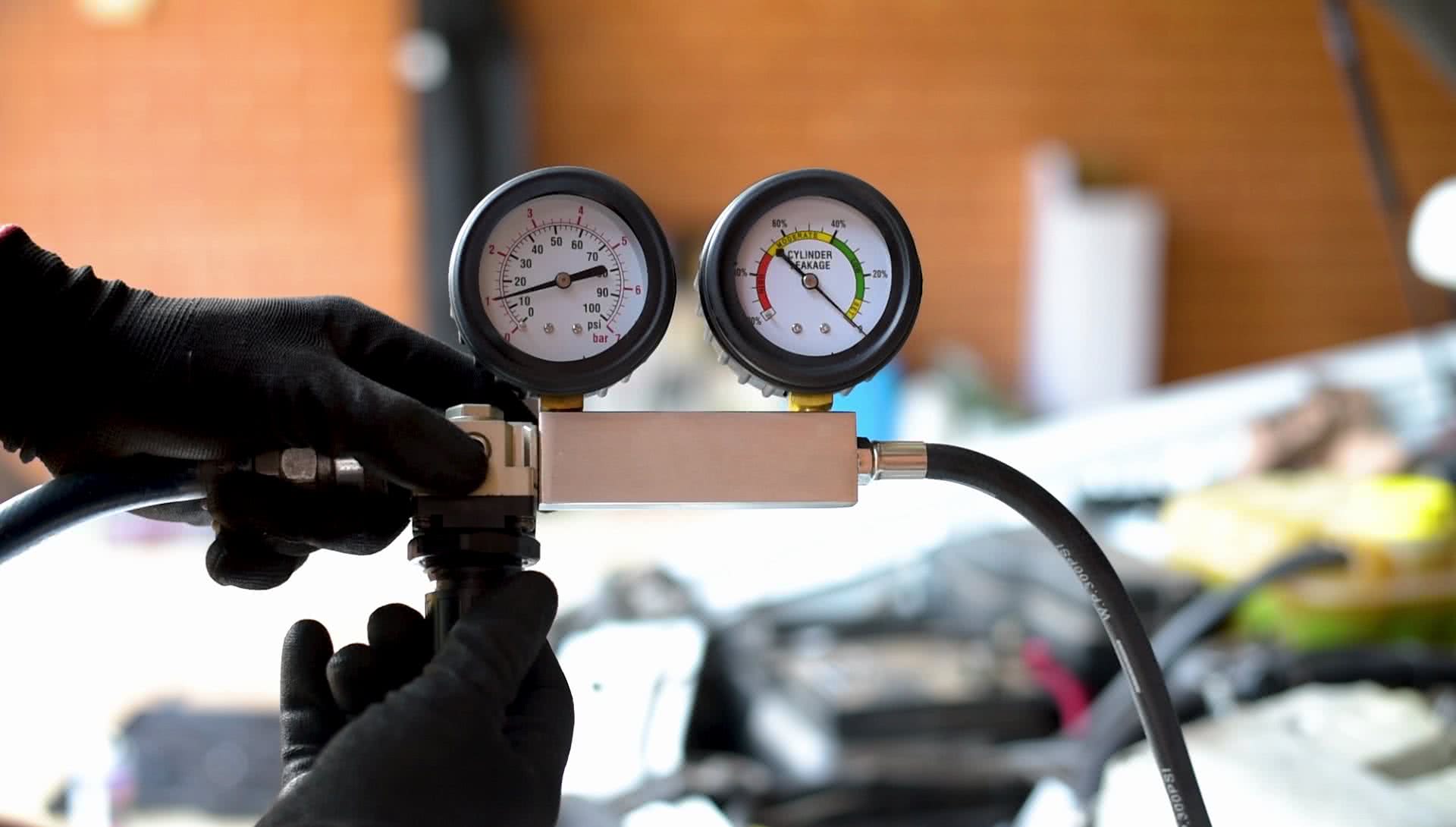

Five to 10 percent loss indicates an engine in great to good running order. Even for normally aspirated engines respectable leakage numbers would be anywhere from 8 to 12 percent with a variation between cylinders of 4 to 5 percent but its possible the variation could. Consequently good cylinder leakdown readings should be below 5 8. Leak down needs to be taken lightly. One test you could try is to pump a shot or two of engine oil into a cylinder crank the engine over for a dozen rotations or so and try the compression test again. The tester is connected to an air source and is attached to the engine through the spark plug hole.

Doing a leak down test is a fairly simple matter.

.ashx?modified=20180416133242)