An oil to water cooler passes the engine oil through a heat exchanger element of some sort that enables the engines coolant to either add heat to cold oil or to pull heat from excessively hot oil. The oil cooler is connected to the lubrication system in parallel with the main oil pressure line.

Hydraulic Oil Coolers Ej Bowman

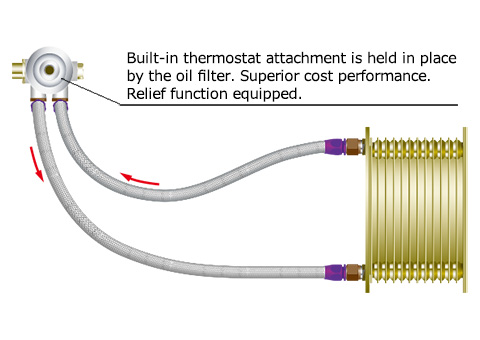

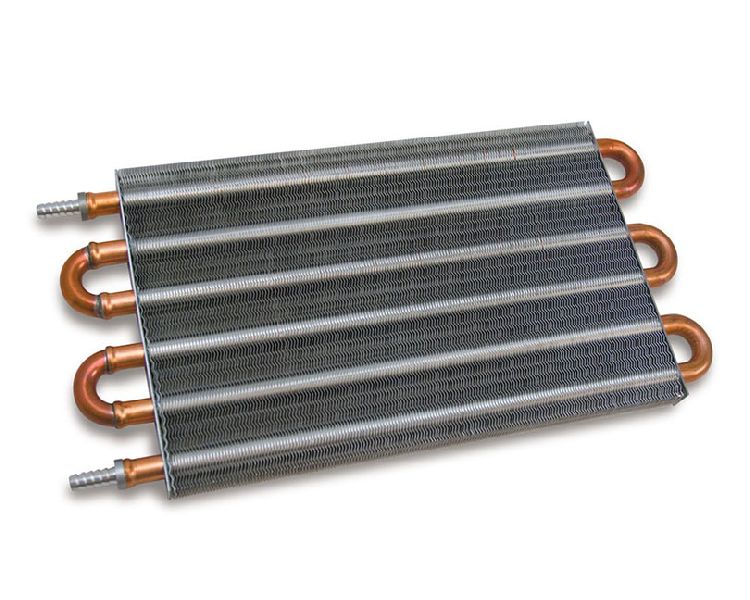

Types of oil coolers. These products can be availed from us nominal market price. There are four different types of transmission coolers. Indirect cooling in indirect cooling the oil is cooled through the heat transfer of an intermediate medium wehber explained. Oil cooling is the use of engine oil as a coolant typically to remove surplus heat from an internal combustion enginethe hot engine transfers heat to the oil which then usually passes through a heat exchanger typically a type of radiator known as an oil coolerthe cooled oil flows back into the hot object to cool it continuously. Tube fin transmission coolers. The air cooled oil cooler consists of brass tubing to which cooling fins are soldered.

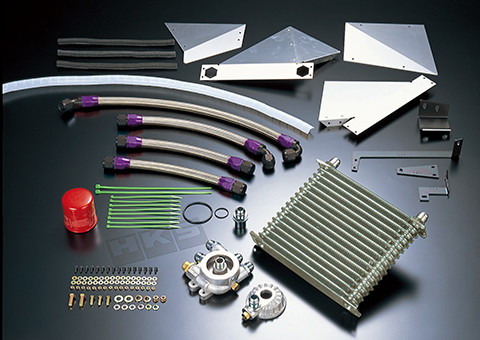

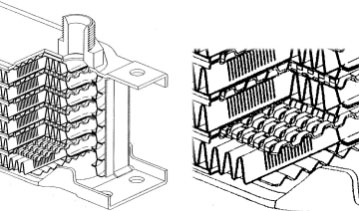

Advantages and disadvantages overall adding an oil cooler to a vehicles engine will help to extend the life of the oil therefore extending the life of the engine. Each of which has their own set of benefits compared to the others. The new flex a lite engine oil coolers use turbulized fins inserted into the internal cooling plates to avoid an outer layer of fluid forming near the plate walls that is cooler than the fluid flowing through the. Engine oil coolers are generally broken into two types. Premier offers fin tube type oil coolers to cool transformer oil lube oil tempering oil etc. Oil is cooled in tubes using ambient air with the help of fan et motor.

The oil circulated in the tubing by the oil pump is cooled by air when the vehicle is in motion. The plate heat exchanger design used is conventionally in vacuum production. In many cases oil coolers are added to trucks motor homes and other types of heavy vehicles. Tube and fin coolers plate and fin stacked plate and heat sink transmission coolers. In severe conditions engine coolant alone isnt enough to protect the engine oil and internal components from premature wear or failure. The up scaled production material was used for the manufacture of automotive plate type oil coolers.

Oil coolers may be of the air cooled or water cooled type. Oil coolers air oil cooler with ac motor lac series europe air oil cooler with dc motor ldc series europe qac quiet air oil cooler with ac motor europe water oil cooler shell tube st series americas swo shell and tube water oil coolers europe brazed plate water oil. Wehber described the two basic types of oil coolers. Indirect and direct cooling. Keep reading for more information about the coolers. And therefore it also offered a good opportunity to assess both the flux free brazing performance and post braze internal cleanliness of the new material.

The new flex a lite engine oil coolers provide up to 4 times the heat rejection compared to typical low cost coolers.