Theyre available for download if youd prefer and want to own it just click save symbol on the web page and itll be instantly. It combines the best of servo and stepper motor technologies and delivers unique capabilities and enhancements over both while at a fraction of the cost of a servo system.

Wiring Diagrams

Two phase motor connection. How to wire a three phase motor. The first step is to figure out the voltage of your phases. Follow electrical technology on facebook twitter instagram pinterest youtube linkedin to get the latest updates or. The second transformer is connected to a center tap of the first transformer and is wound for 866 of the phase to phase voltage on the three phase system. Three phase motor connection reverse and forward power and control wiring diagrams. On off three phase motor connection power control schematic and wiring diagrams.

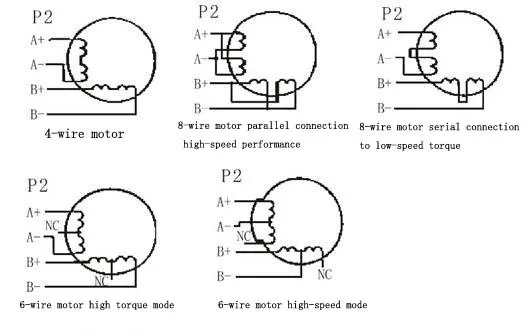

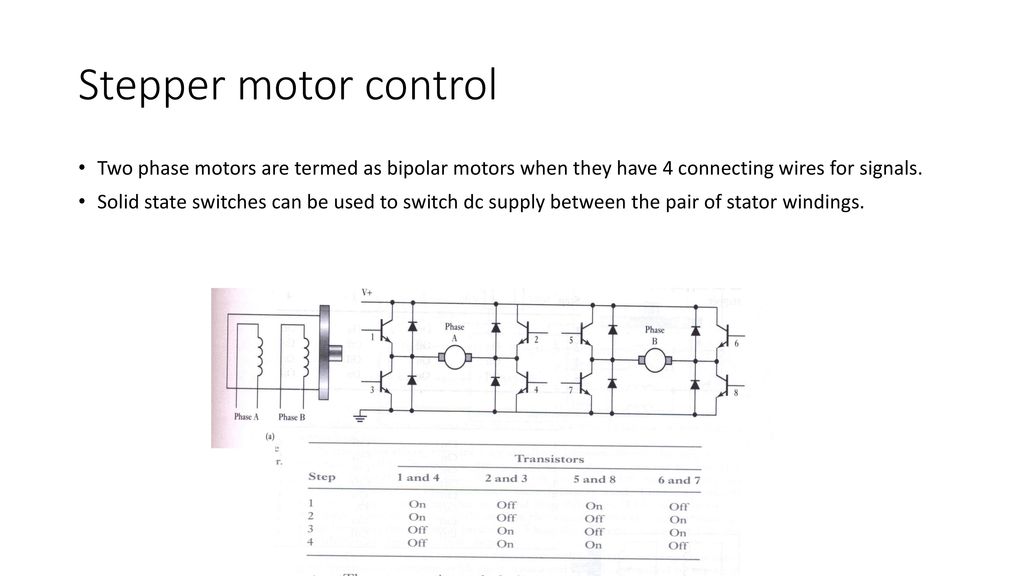

Control 3 phase motor from more than two buttons power control diagrams. So if you desire to acquire all of these outstanding photos about stepper motor wiring diagram click on save link to store the images in your personal computer. 1 x closed loop stepper driver 0 85a 20 80vac30 110vdc for nema 34 stepper. It shows the components of the circuit as simplified shapes and the capacity and signal contacts between the devices. Two phase motor wiring diagram wiring diagram is a simplified customary pictorial representation of an electrical circuit. Three phase motor control installation wiring diagrams.

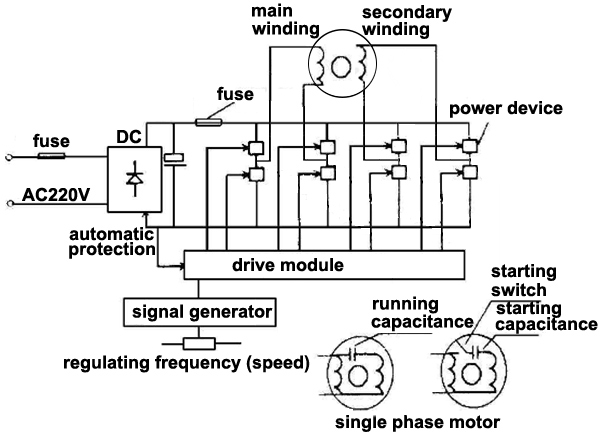

A two phase motor is a system that has two voltages 90 degrees apart which is no longer in use nowadays. Check more diagrams here. This video will show you how to connect a single phase motor with two capacitors. All about electrical electronics engineering technology. One transformer primary is connected across two phases of the supply. 2 phase 1440 rpm clutch plate motor connection.

In practical terms a three phase motor will need to be wired in one of the configurations described on its faceplate. That being said there is a wide range of different motors and what you have on hand can be completely different. They require 2 live and one ground wire that work in two phases. The alternator is composed of two windings placed at 90 degrees from each other. The system includes a 2 phase stepper motor combined with a fully digital high performance drive and an internal encoder which is used to close the position velocity and current loops in real time just like servo systems. A three phase motor must be wired based on the diagram on the faceplate.

Starting stopping of 3 phase motor from more than one place power control diagrams. 2 speeds 1 direction 3 phase motor connection tap wound control diagram control diagram. A motor with a start and run capacitor and a start and run coil. Two phase power can be derived from a three phase source using two transformers in a scott connection. Facebook twitter linkedin tumblr pinterest reddit vkontakte whatsapp telegram share via email print. In the united states for low voltage motors below 600v you can expect either 230v or 460v.