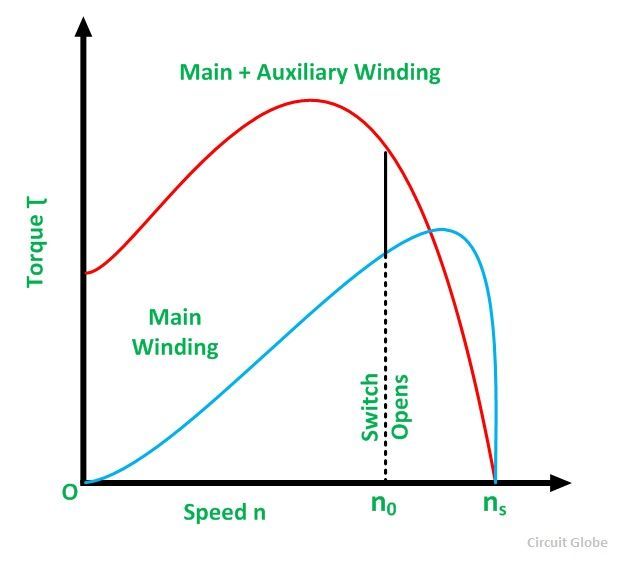

Single phase motor wiring diagram forward reverse single phase motor reverse and forward connection with capacitor wiring diagram. Also read about the speed torque characteristics of these motors along with its different types.

Eb0 Single Phase Compressor Wiring Diagram Wiring Library

Single phase motor wiring diagram with capacitor start pdf. The light ing distribution panels are the source for single phase power supply. Wiring diagram single phase electric motor wiring diagram explained motor run capacitor wiring diagram. Learn how a capacitor start induction run motor is capable of producing twice as much torque of a split phase motor. Goodman run capacitor wiring diagram wiring diagram explained motor run capacitor wiring diagram. Fan motor cc c h f dual capacitor single phase field supply l1 l2 grd grounding screw c s r c y comfort alert t1 t2 l1 l2 hps lps used in r410a models only contactor r start capacitor start relay 5 2 black w with k hash comp orange low voltage terminals see note 6 red red defrost thermostat t2 dft test t1 t2 c y o w2 r dft e c y o w2 r e df1 df2 black black reversing valve solenoid yellow cc w black blue black defrost control board yellow 1 cch yellow l l select models only black blue. Click here to view a capacitor start motor circuit diagram for starting a single phase motor.

Single phase capacitor start capacitor run motor wiring diagram single phase motor wiring diagram with capacitor. If not the arrangement wont work as it should be. Frequent stopstarts andor changing of the direction of rotation will damage the motors capacitors and winding. You may be capable to know specifically if the projects ought to be finished that makes it much simpler for you to effectively manage your time and efforts. Wondering how a capacitor can be used to start a single phase motor. Furthermore wiring diagram provides you with enough time body during which the projects are to become finished.

Capacitor start single phase motors danger. Just as in the three phase motor diagram the motor shows the power supply lines as being identified with the t. Click on the image to enlarge and then save it to your computer. Single phase motor wiring diagram with capacitor baldor single phase motor wiring diagram with capacitor single phase fan motor wiring diagram with capacitor single phase motor connection diagram with capacitor every electrical arrangement is made up of various unique pieces. 2 align motor accurately using a flexible coupling if possible. This type of motor is designed to provide strong starting torque and strong running for applications such as large water pumps.

The basic diagram view a shows a circle with two leads labeled t1 and t2. 3 mounting 1 mount motor securely on a firm flat base. For most shore facility applications this is the case. Not only can you locate various diagrams but you can also get step by. Each component ought to be placed and linked to different parts in particular manner. Wiring diagram not just offers in depth illustrations of whatever you can do but additionally the processes you should stick to although carrying out so.

Assortment of single phase motor wiring diagram forward reverse. Schematic diagrams for the single phase motors. All ball bearing motors horizontal or vertical normal thrust grease lubricated may be mounted in any position. Refer to nema mg1 1441. 3 v belt sheave pitch diameters should not be less than the nema recommended values. The reconnection must be carried out by qualified electrician.

In many cases the single phase motors on board a ship will be wired into the lighting distribution panels. Capacitor start capacitor run induction motors are single phase induction motors that have a capacitor in the start winding and in the run winding as shown in figure 12 and 13 wiring diagram. Wiring diagram single phase motors 1empc permanent capacitor motors 1empcc capacitor start capacitor run motors electric motors limited when a change of direction of rotation is required and a change over switch is to be used it will be necessary to reconnect the termination on the terminal block. For drive recommendations consult with drive or equipment manufacturer or sterling electric.