Three steps on how to do an engine leakdown test pressure reading. If youre performing a leak down test on a single cylinder you.

Pressure Testing An Engine S Cooling System Isn T A Bunch Of

Leak down test procedure. A common test of an engines ability to compress the air fuel mixture is an engine compression test. A cylinder leak down test requires the removal of all the spark plugs. How to perform a leak down test 1. An engine leakdown test is a compression test in reverse. The crankshaft is then turned so that each piston is at top dead centre. It shows the percentage of leakage and pinpoints the part causing the compression leak.

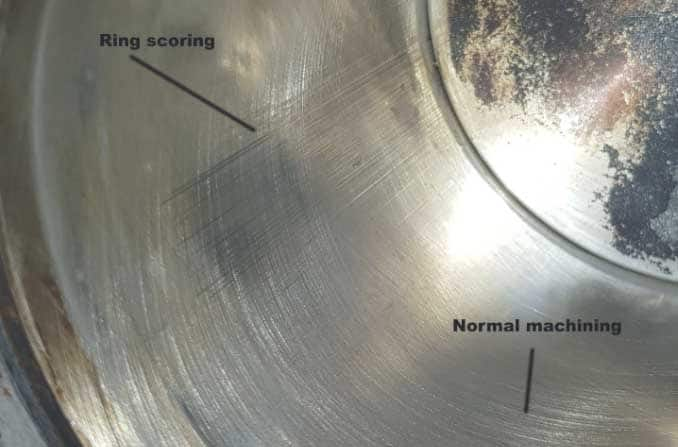

The only way air pressure can escape is through the valves piston rings and head gasket. It is a good practice to start with the number one cylinder and follow the engines firing order. Performed a cylinder leakage or leak down test after a cylinder balance and a cylinder pressure test has verified a problem with the cylinder. Locate top dead. The intake valve leads to the intake manifold and the exhaust valve leads to the exhaust tailpipe. If you detect a significant amount of air escaping past the intake valve during the leakdown test try tapping on the intake.

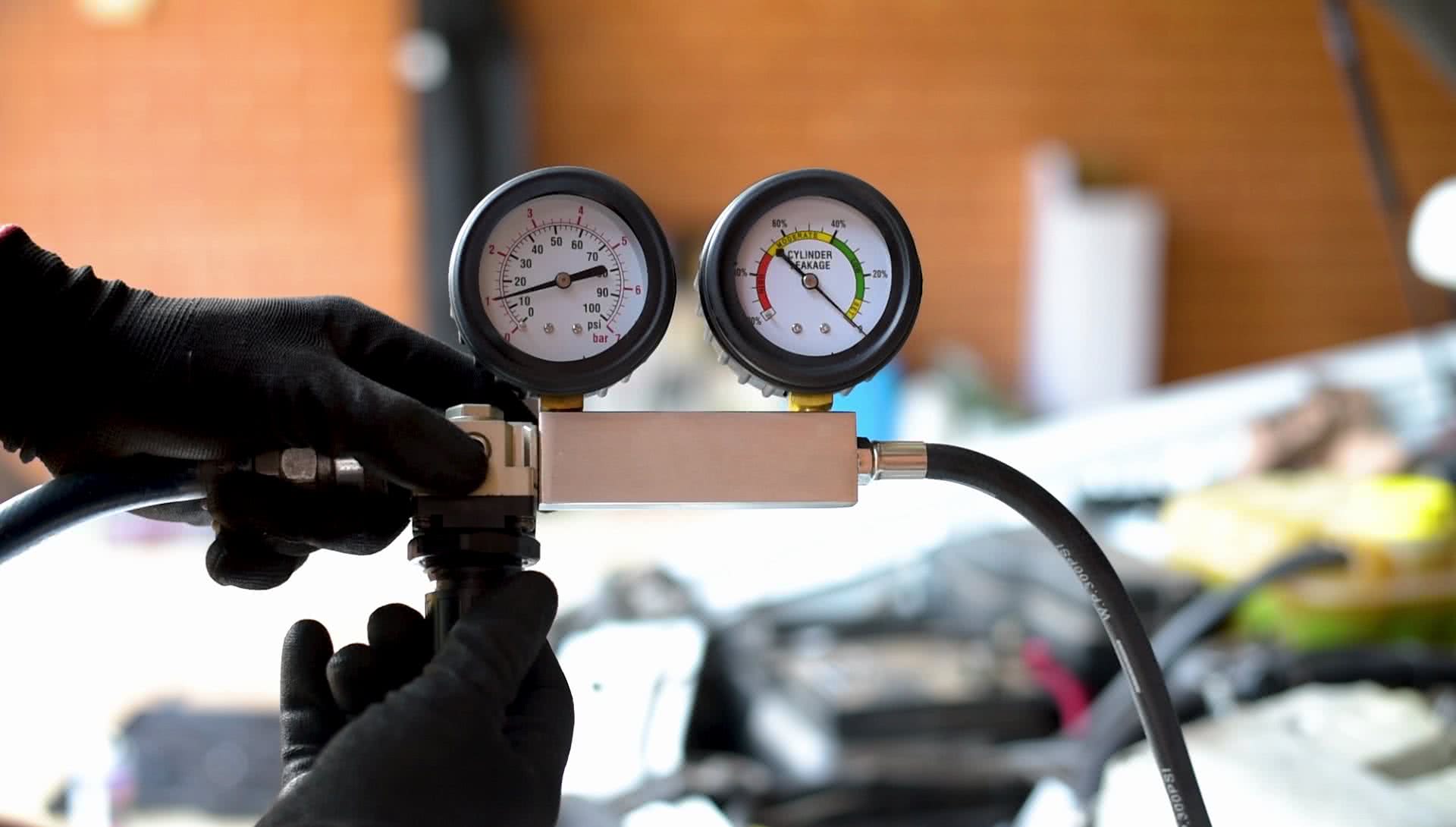

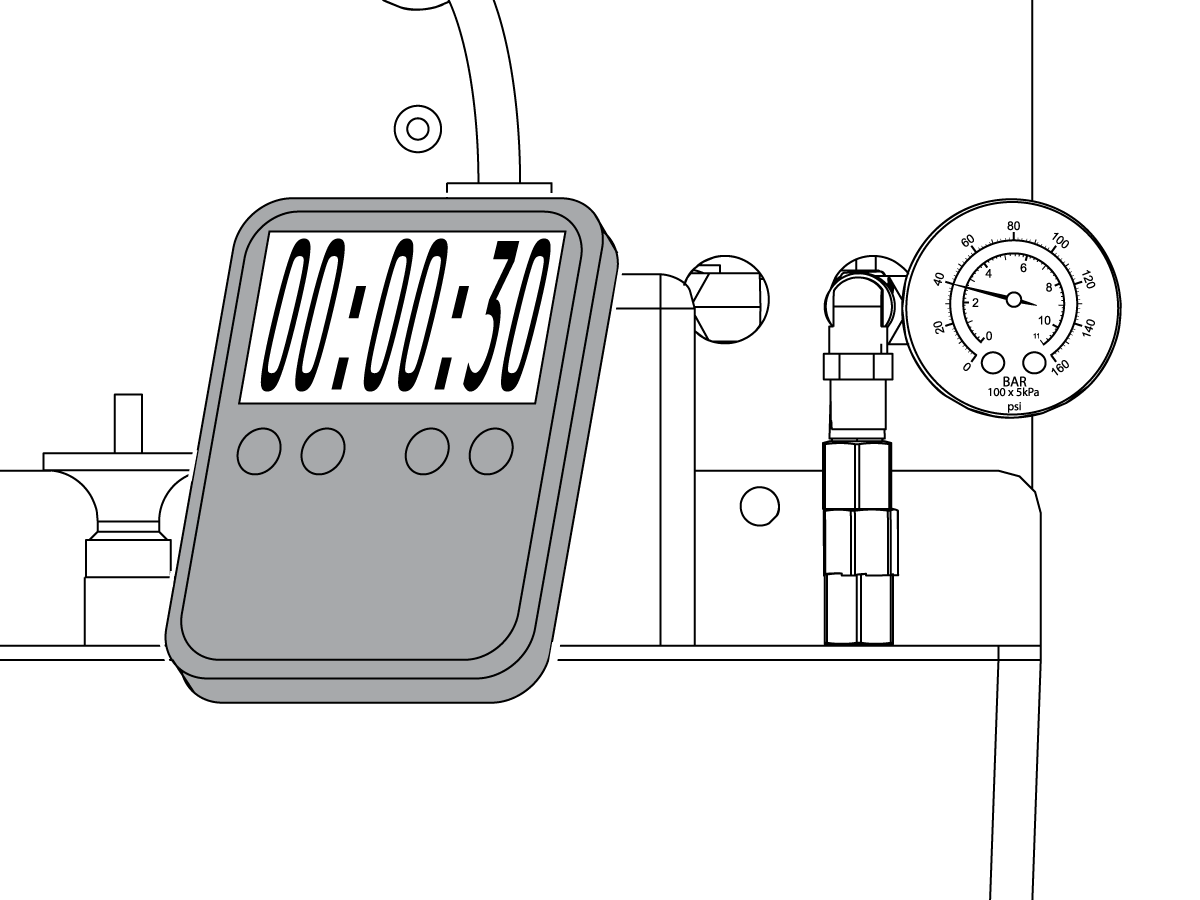

A leak down test also includes putting a pressure gauge into each cylinder in the engine though in this instance it is a leak down test device that is inserted with a display that incorporates two separate dials or displays. Youll need a leak down tester industrial grade air compressor one large enough to run air tools a. A leak down test will pressurize the engine through the spark plug hole while at top dead center tdc. So what is considered acceptable leakage. A threaded coupling is screwed into a spark plug hole. Compressed air 80 to 90 psi is then fed into the cylinder.

When at tdc all intake and exhaust valves will be closed and the piston will be at the top of its stroke. Make sure the engine is off. The valves rings and head gasket seal the combustion chamber. A leak down test requires all the spark plugs be removed. Turn the crankshaft so that each piston is at top dead center both valves closed when each individual cylinder is tested. The area where leakage presents the most concern is the intake valve.

Perform a cylinder leakage test by injecting regulated shop air into the cylinder heads spark plug hole then visually searching and listening for a leak. Instead of measuring the engines ability to. Remove the spark plug and place the problem cylinder at tdc top dead center of the compression stroke.