How to perform a leak down test 1. Remove the plug boot from the no.

How To Perform A Leak Down Test Car Bibles

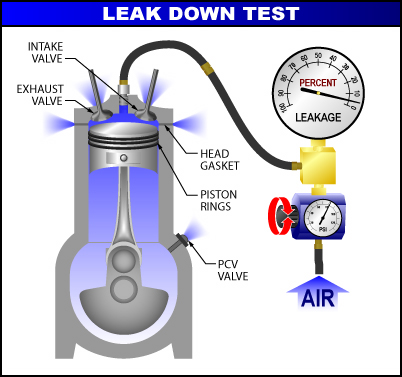

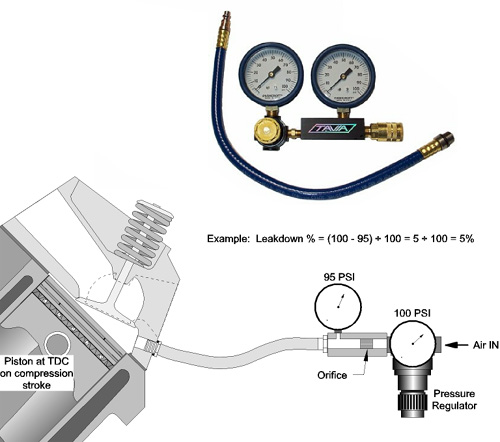

How to do a leak down test. When the leak down test tool is attached to the cylinder the next task is to attach the tool itself to the air compressor. Insert a large screwdriver or long thin dowel into the plug. Remove the screwdriver and hook the leak down test tool into the spark plug hole. A threaded coupling is screwed into a spark plug hole. There are basically two different. A common test of an engines ability to compress the air fuel mixture is an engine compression test.

Make sure the engine is off. Place the car into gear if you can but also engage the parking brake so it wont roll. An engine leakdown test is a compression test in reverse. Chocks behind the wheels can also be useful. If youre performing a leak down test on a single cylinder you. Put manual transmissions in gear and firmly set the parking brake to keep the compressed air from turning the engine.

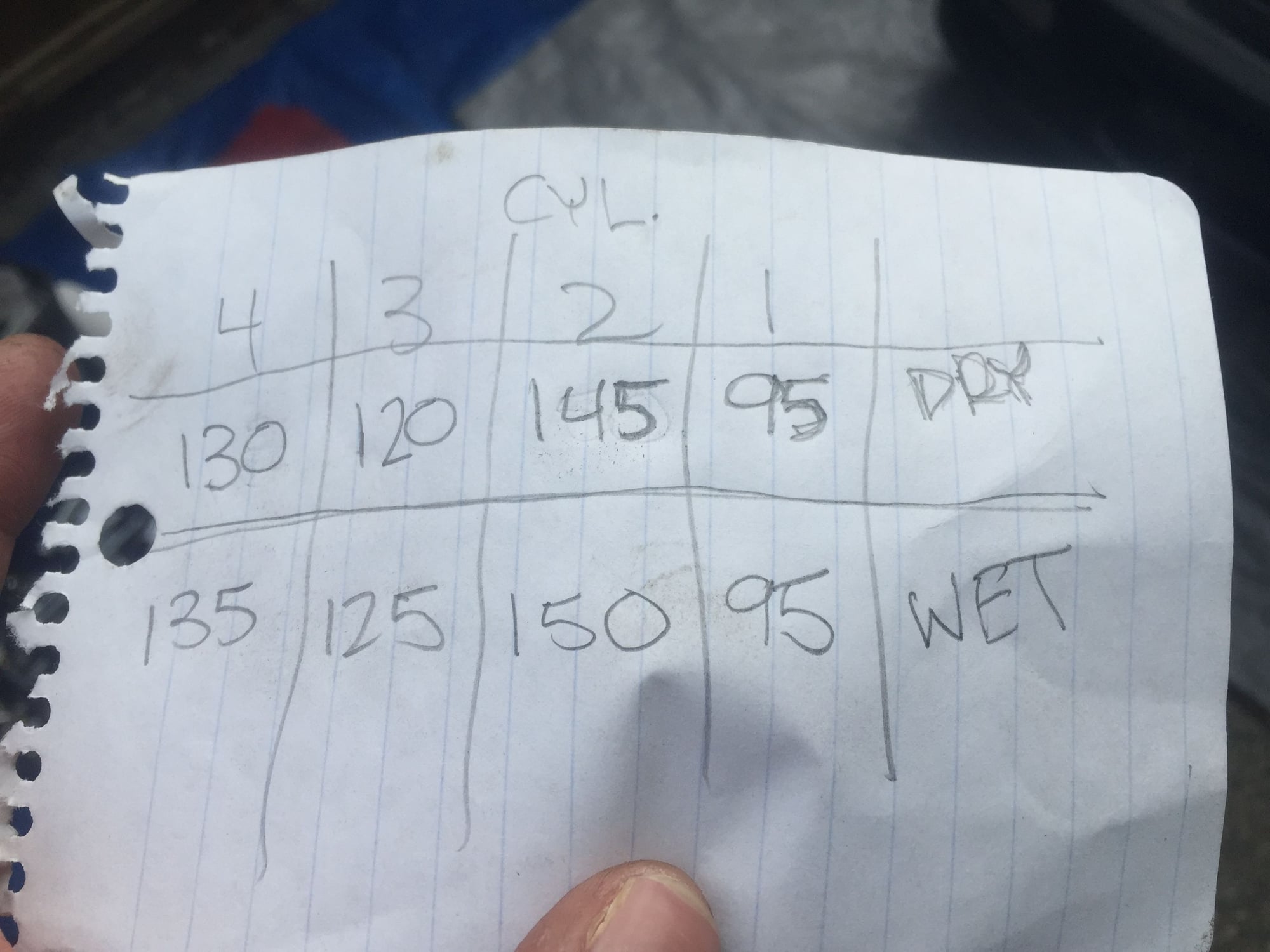

Use the spark plug socket and ratchet to remove the no. Locate top dead. Toolslets start with the leakdown tester itself. Three steps on how to do an engine leakdown test pressure reading. The crankshaft is then turned so that each piston is at top dead centre. Compressed air 80 to 90 psi is then fed into the cylinder.

Instead of measuring the engines ability to. A cylinder leak down test requires the removal of all the spark plugs. Youll need a leak down tester industrial grade air compressor one large enough to run air tools a. Lets take a look at how to perform a cylinder leakdown test properly and what you can learn from the results.