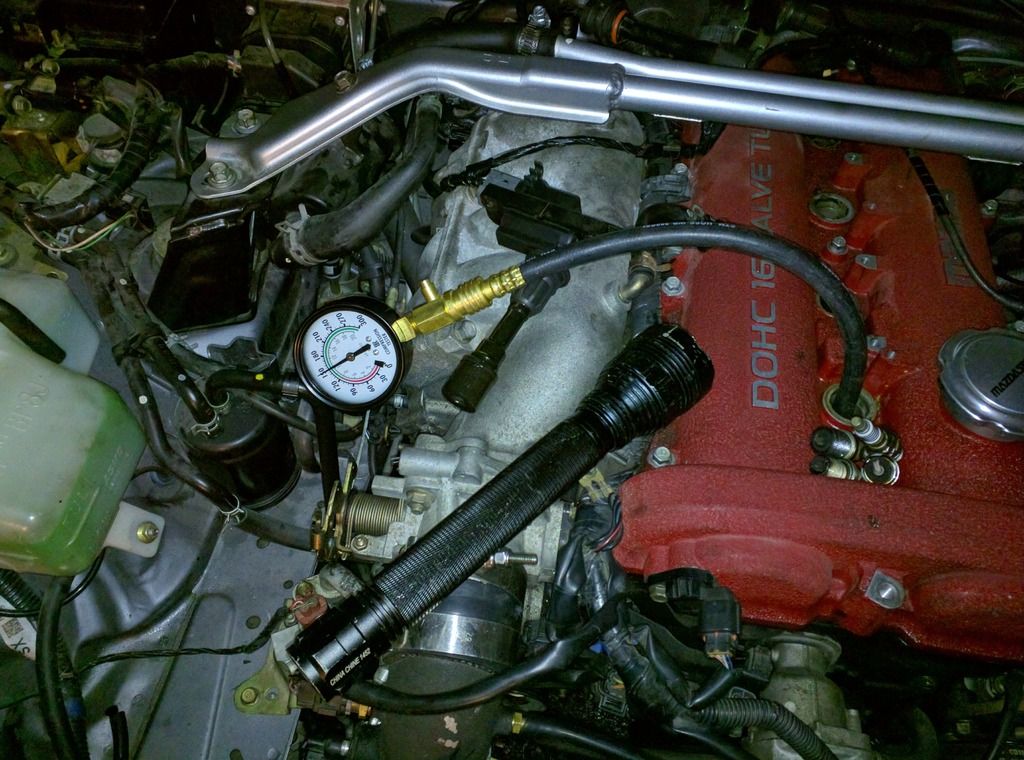

These gauges dont cost much and theyre easy to use. Youll also need to disable your ignition system.

Oil Amp Fuel Deere Yanmar 17mm Compression Test Adapter

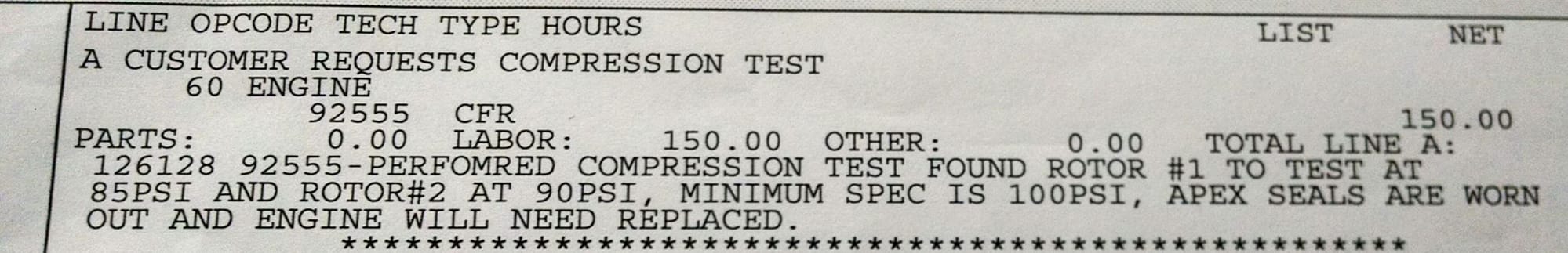

How much is a compression test. A compression test reveals the condition of your engines valves its valve seats and piston rings and whether these parts are wearing evenly. To perform the test crank the engine 4 times by turning the key in your cars ignition then check the compression gauge for the result. The cost of this service or repair can vary by location your vehicles make and model and even your engine type. Healthy engines should have compression over 100 psi. The test is going to depend on the mechanic performing the job your geographical location the make and model of the vehicle the type of engine and if a leakdown test will be performed as well. A compression check can indicate that the piston rings are working properly and that the cylinders are in good condition.

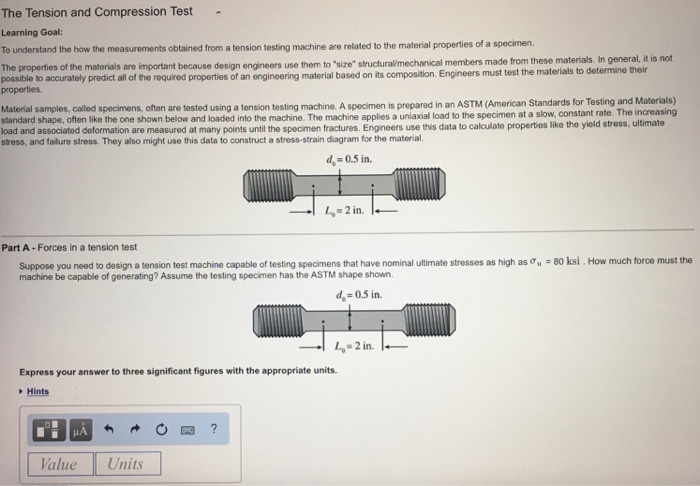

After you get a result for the first cylinder repeat the. Get the engine up to operating temperature by running it for a while or you can do your compression test after a drive. On average for the compression test itself plan on spending anywhere from 120 to as much as 250. Furthermore that reading should be above 135 psi. Before you begin the compression test the engine needs to be warm. Attach the compression test adapter into the cylinder nearest the front of the engine then connect the gauge to the other end of the adapter hose.

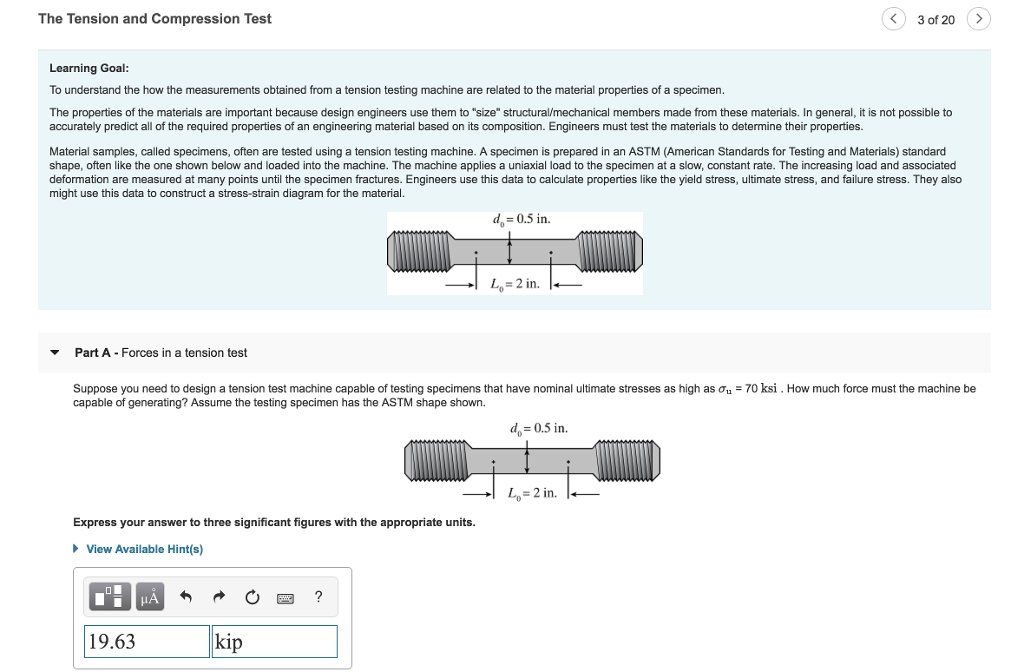

The test measures how much pressure is built up by the motion of the piston inside the cylinder given in pounds per square inch psi. The most desirable situation is that all cylinders give the same or close to the same reading. Some parts of the engine can be very hot. The average cost for an engine compression test is between 126 and 161. Estimate does not include taxes and fees. We are going to need to crank the starter to turn the.

Similarly a compression of 85 psi or lower is extremely bad. To determine whether pressure is escaping from the engine you need to check the compression in the cylinders with a compression gauge which measures the amount of pressure that the piston exerts on the fuelair mixture before the spark plug fires the mixture. A compression test is designed to reveal the condition of your engines valve train and piston rings. Specifically parts like intake and exhaust valves valve seats head gaskets and the piston rings are common parts that can wear out and lead to reduced compression. Labor costs are estimated between 126 and 161. As a general rule a compression of 135 psi or better is excellent.

While each engine and manufacturer are unique and have different levels of.