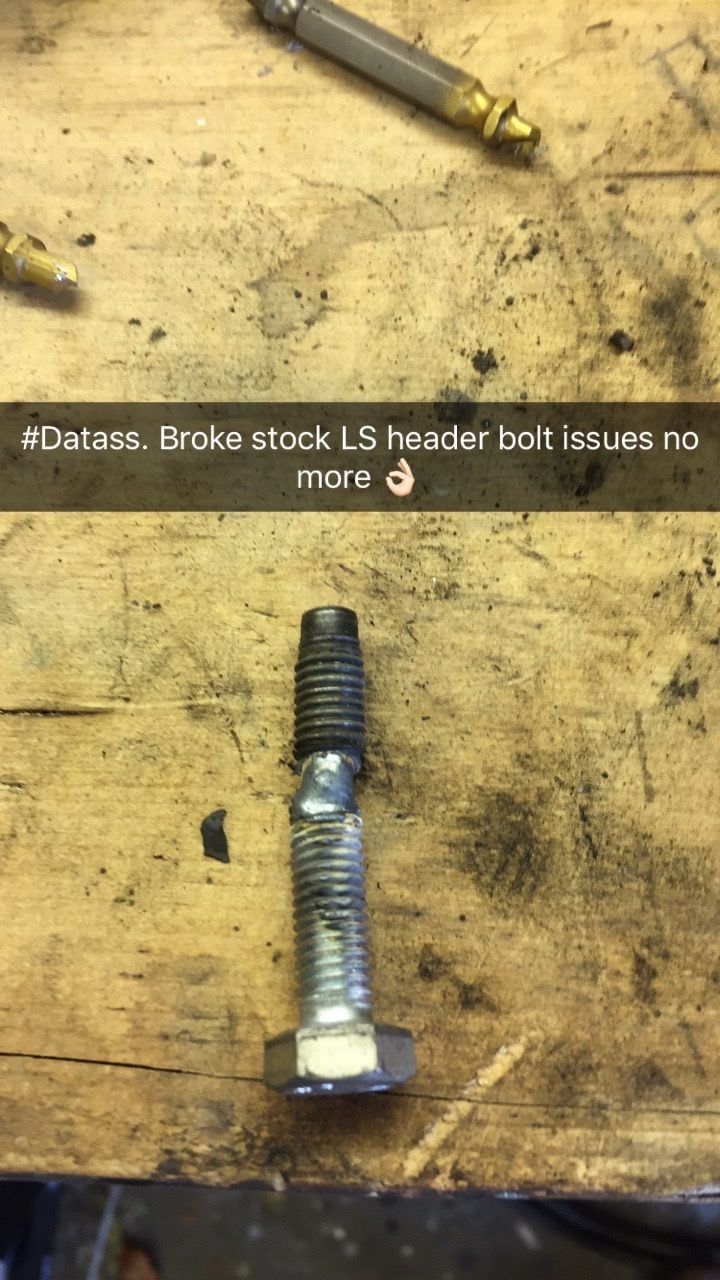

Tightening header bolts into aluminum heads. If a bolt is not coming up to normal torque or is not holding a reading it means trouble.

Lt1 Arp Head Bolt Torque Specs

Header bolt torque aluminum heads. Jump to latest follow. Screw in rocker arm studs. Intake manifold bolts cast iron head. On each head bolt to make sure none have been missed and that the bolts are retaining torque normally. Discussion starter1mar 10 2005. I have an aluminum head zz4 in my 68 and recently lost a header bolt.

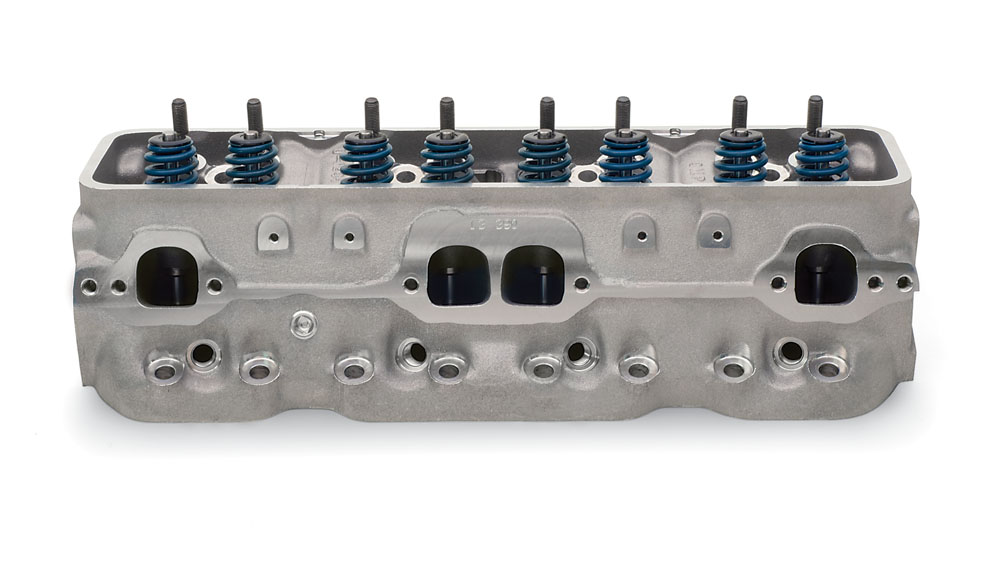

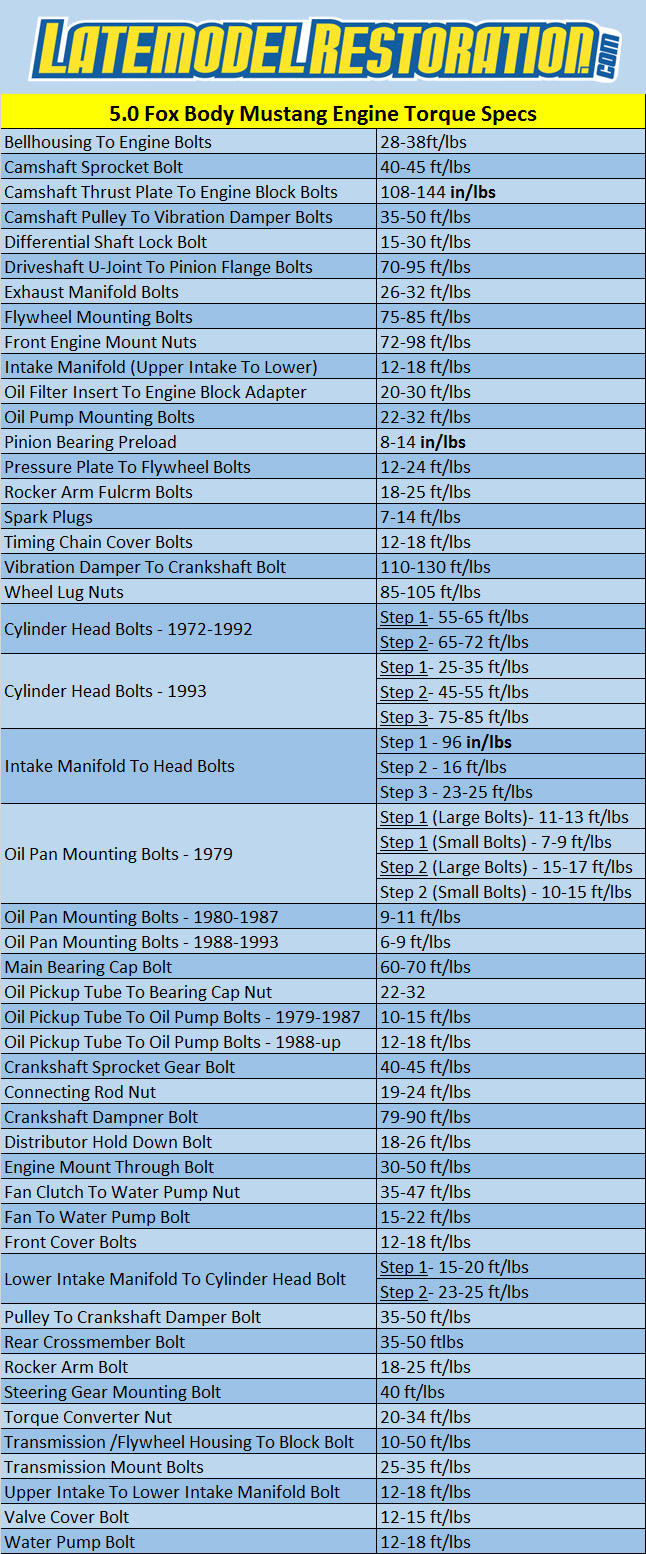

For head studs or aftermarket bolts check your instructions sbc studs are available in a ton of different styles depending on heads and stud diameters. I use the small head stainless arp header bolts and because of the configuration. Use a straight edge and check for flat. It will take only a modest amount of torque to seal the header anyway. Some people do only 1 or 2 steps to reach the final torque. These specs are for stock type bolts with light engine oil applied to the threads and the underside of the bolt head.

Main cap bolt 396 427 2 bolt 95 ft lbs. Moly and other lubes offer reduced friction and increased bolt tension which will affect the torque figure. I blew an exhaust gasket and decided to fix the whole enchilada correctly. Main cap bolt 396 454 4 bolt inner and outer 110 ft lbs. Cylinder head bolts short. Hey i thought i would share a recent experience and some tidbits that i searchedalmostendlessly for.

Aluminum has a higher coefficient of expansion than cast iron. For example i got the arp head studs and only torqued my heads down to 115 lbsft with moly lube. Cylinder head bolts long. If there are gaps or warpage have a machine shop mill the mating surface flat. Yes your torque specs will be different with aluminum heads than cast. You need to follow the instructions that came with the bolts.