The answer is no. Deliberately placing the pinion at a lesser.

How To Determine Engine Pinion Angle

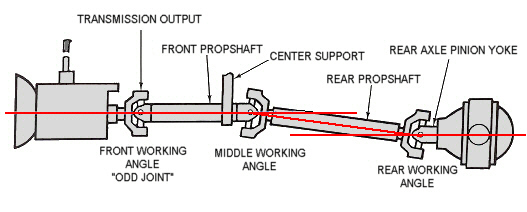

Driveshaft alignment side to side. Inflate all tires to the pressure at which they are normally operated. Compare speedway weld on spring pad for 3 inch axle tube. Compare gm transmission front driveshaft slip yoke 27 spline 8 inch. Speedway steel drive shaft. Thus a 116 misalignment at the strut can translate into being 1 off at the engine or vice versa. The first spot is the transmission angle and second is the shafts angle.

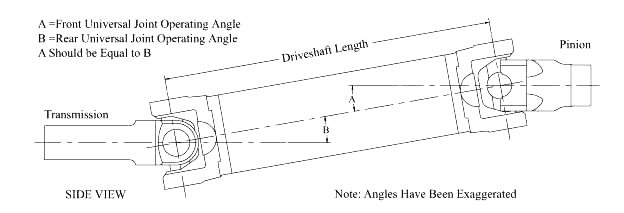

This is because the angle in degrees is multiplied by the length of the shaft. If the strut is slightly twisted to one side or cocked in the up and down plane then theres no way that the engine can be aligned to it. And the angles should be kept to a minimum if at all possible. I have been working to install it with a triangulated four link setup with coilovers. Compare intercomp 102144 digital angle gauge. If youre lifted with a sye kit and double cardan joint drive shaft then the pinion should point directly at the transfer case output when you look from the side.

How to top off your ac system duration. I bought an 88 rearend out of a ford ranger because the pl to pl dimension is the same as the old axle. If your race car must have drive line angles from a design standpoint the angle of the drive shaft to both the transmission output shaft and the pinion shaft should be equal and also opposite. View 32 8999 more info. View 72 1499 more info. Park the vehicle on a surface which is as level as possible both from front to rear and from side to side.

View 31 7499 more info. As a driveshaft turns at a given angle the joint moves in a forward to back motion. Use the following procedure to check driveshaft angles for proper u joint operating angles. View 9 6900 more info. The movement makes an x on paper if you were to map it out. I guess youre asking whether you need any vertical angle if you have a good 3 angle to the side.

On a street driven vehicle the goal is for the pinion to move equally on either side of ideal to produce an acceptable compromise for driver comfort. The pinion or the engine or both need to be offset horizontally or vertically or both enough to give about a 3 degree angle between those centerlines and the driveshaft. Bright side recommended for you. Quite simply if the x or angle measurement on the top isnt the same as on the bottom you will end upwith a bicycle cranktype. The primary concern would be that the transfer case output and the axle pinion are parallel from a side to side stand point when you look from the top or bottom.