The leakdown test measures how well the cylinder is sealing. The valves rings and head gasket seal the combustion chamber.

How To Do A Leakdown Test Mobil

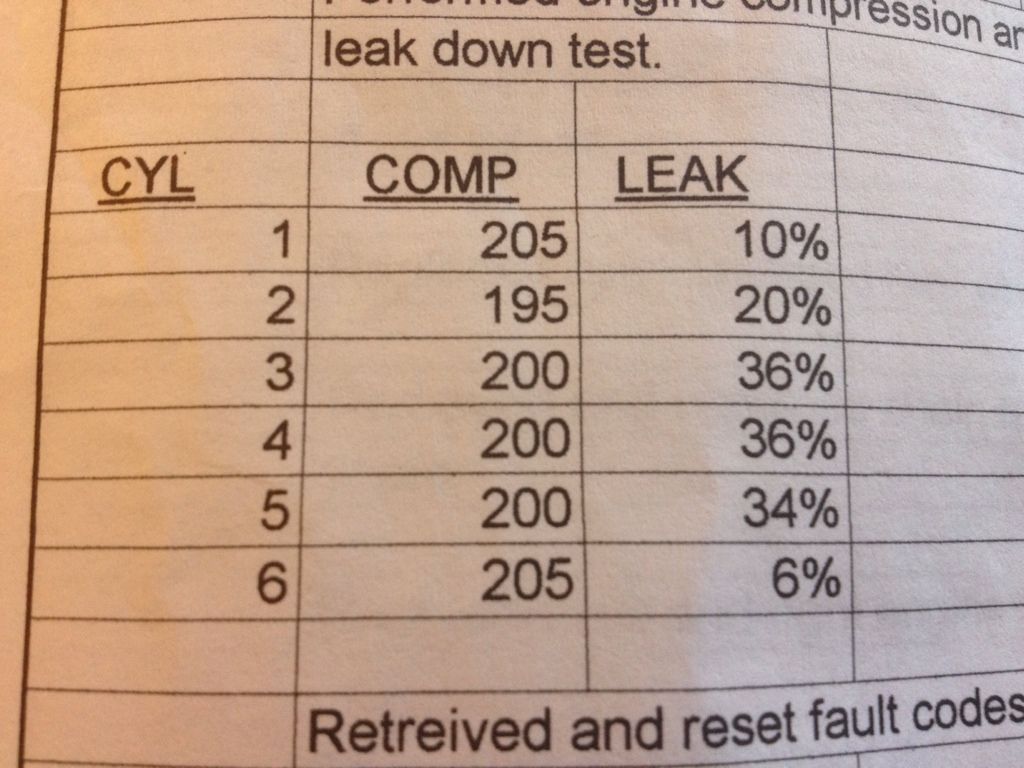

Cylinder leak down test acceptable result. The way to get to the final answer for a given test is. Cylinder leak down is a great tool to diagnose problems but if the engine doesnt have any problems other than what you are testing for id let it go and drive the thing until it is completely broke in. You didnt mention whether there were a couple of cylinders that were greater than 50 60 percent. Also a cylinder leak down test can pinpoint issues in specific areas that other tests can not. No engine will have perfect sealing with 0 percent loss. How you roll the engine over to tdc will also have an effect on leakdown do not back up the crank and dont go even slightly.

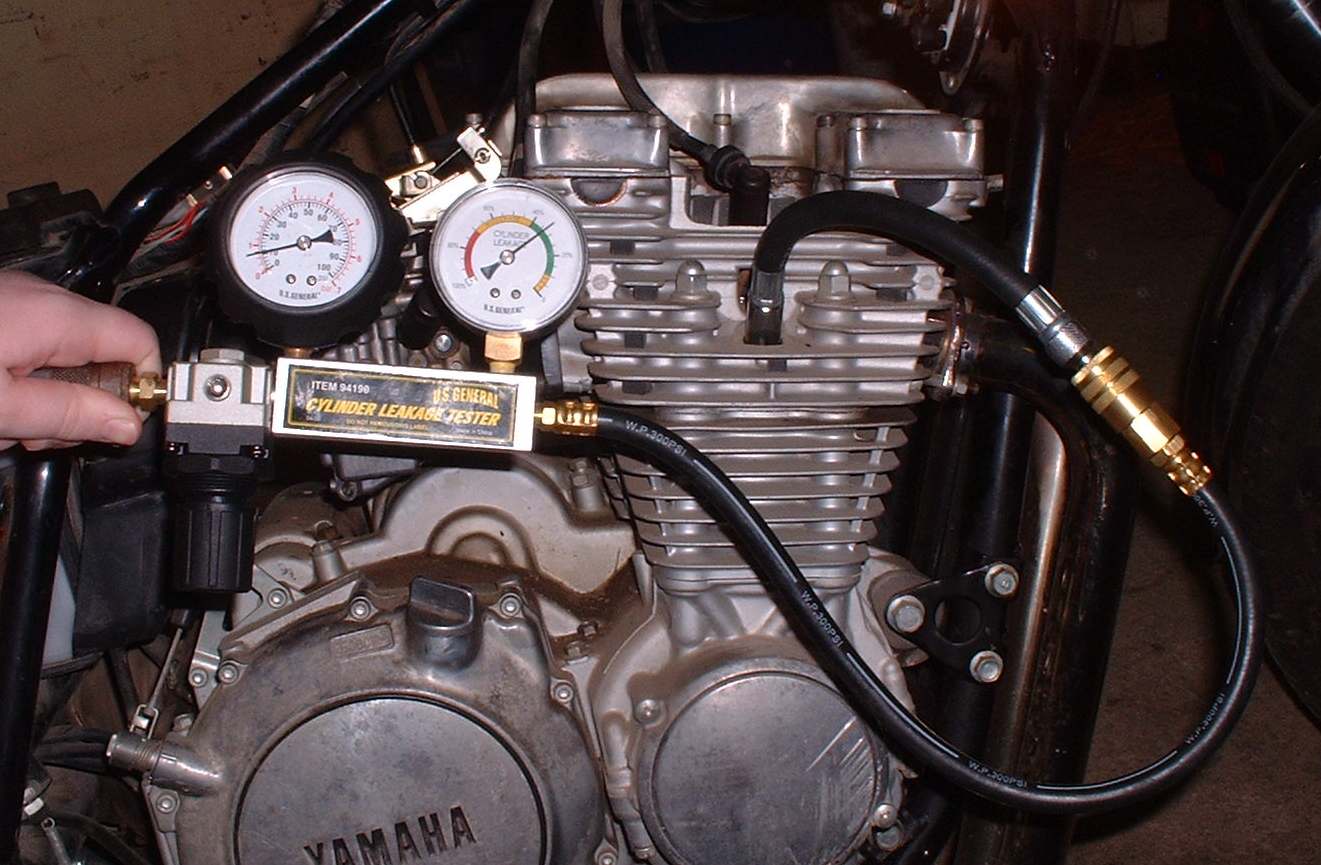

The tester then measures the volume of air needed to maintain a predetermined pressure in the cylinder. This is done by inserting compressed air around 100 psi into the cylinder at tdc and then measuring how much is lost from the seals. The tester is connected to an air source and is attached to the engine through the spark plug hole. So a compression test measures how well your engines cylinders are sealing. A leakdown tester can point out problems that a compression test wont. Doing a cylinder leak down test can tell you more about your engine than you think.

Above 20 percent loss and it may be time for a teardown and rebuild. Consequently good cylinder leakdown readings should be below 5 8. A cylinder leak down or cylinder leakage test is actually similar to a compression test. For example after you connect the 80 psi static pressurized tester to the engine the left side regulator controlled gauge may say something like 70 psi after it drops while the right side engine leakage gauge may say something like 65 psi. Doing a leak down test is a fairly simple matter. Perform a cylinder leakage test by injecting regulated shop air into the cylinder heads spark plug hole then visually searching and listening for a leak.

Then using a similar type of connector as the compression test we fill the cylinder with pressure. Always make sure to test cylinder leakage with the piston at the top of the cylinder. First i would run a compression test looking for weak cylinders. This is where the greatest cylinder wear occurs. Lets say that they were all within 10 percent of each other in pressure with a peak of around 150 to 170 psi. Five to 10 percent loss indicates an engine in great to good running order.

The cylinder leak down test reading is expressed in a percentage. An engine between 10 and 20 percent can still run ok but itll be time to keep an eye or ear on things. In simplified terms if air is pumped into the cylinder at 100 psi and the gauge reads 97 psi then the leak down percentage is 3. The intake valve leads to the intake manifold and the exhaust valve leads to the exhaust tailpipe. It does little good to measure leakage with the piston at.