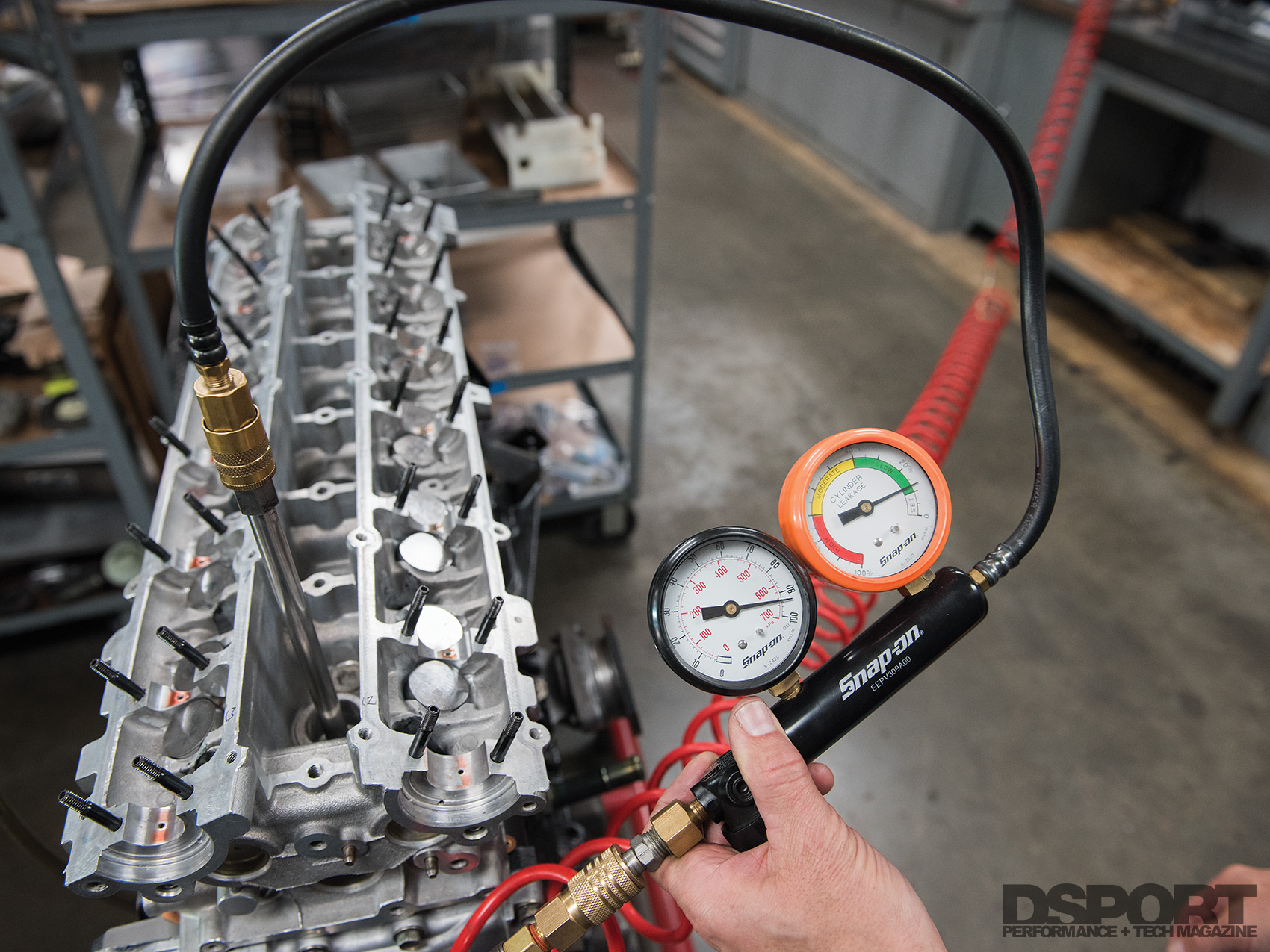

Always make sure to test cylinder leakage with the piston at the top of the cylinder. Sometimes when you remove a head its easy to see that the valves are leaking.

12 Tips To Help Keep Your 2 Stroke Running Strong

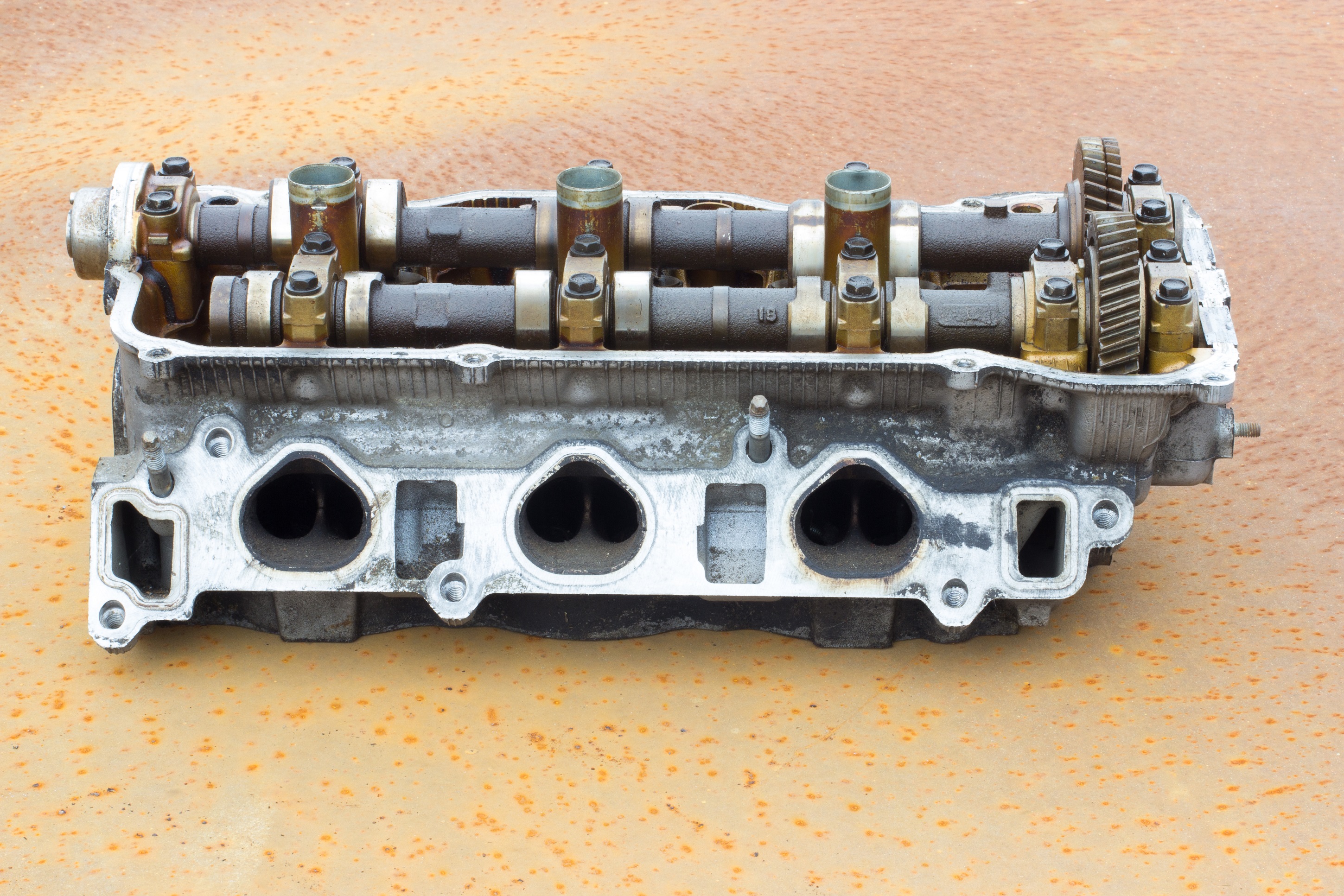

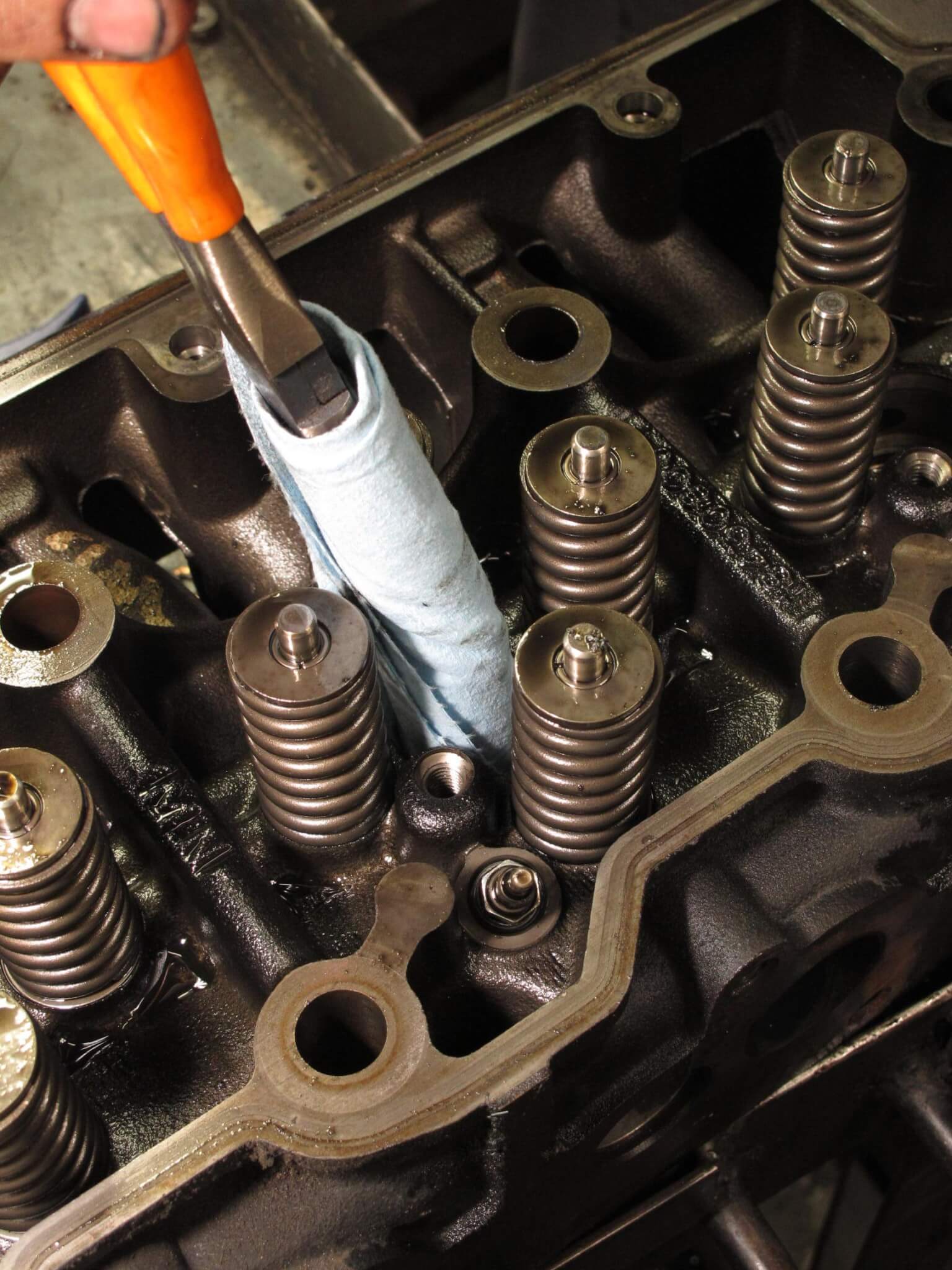

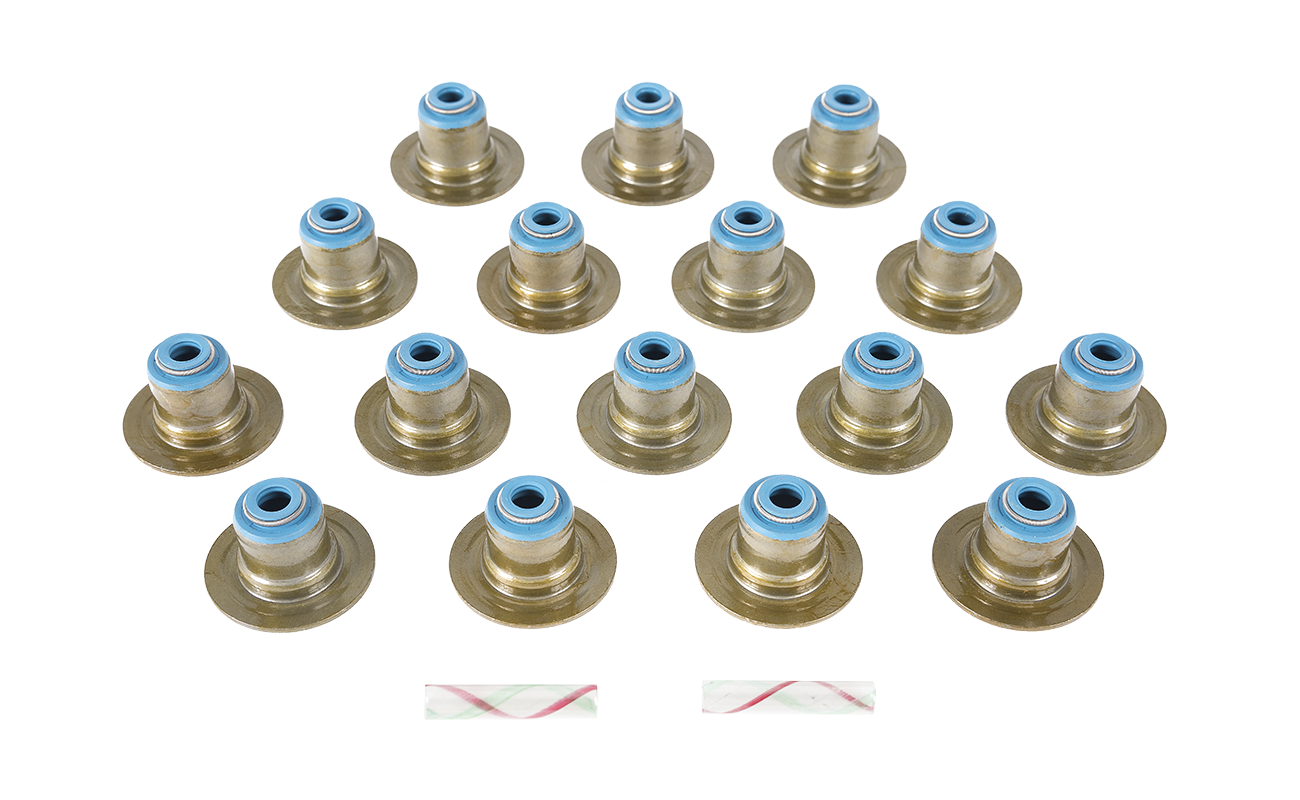

Cylinder head valve leak test. Typically it takes a valve job to repair but this can also occur on a freshly machined head if any work was done improperly or out of center. But a cylinder leak down test takes it to the next level and measures cylinder pressure loss. This is where the greatest cylinder wear occurs. In this video i show you how to water and air pressure test your cylinder heads for valve seating issues right on your bench. A cylinder leak down or cylinder leakage test is actually similar to a compression test. Be sure to blow out the excess water and spray wd 40 onto valve stems.

If you suspect issues with your cylinder heads a water test is an easy way to confirm your suspicions and show the trouble areas drip by drip. It does little good to measure leakage with the piston at. So a compression test measures how well your engines cylinders are sealing. And sometimes its hard to tell. But you dont want to risk putting them back on without knowing for sure. What this test does is show you where it was leaking.

Leaking out the top of the valve if water leaks in and around the cylinder heads imagine how oil gas and air will escape into the wrong places under extreme pressure and temperature.