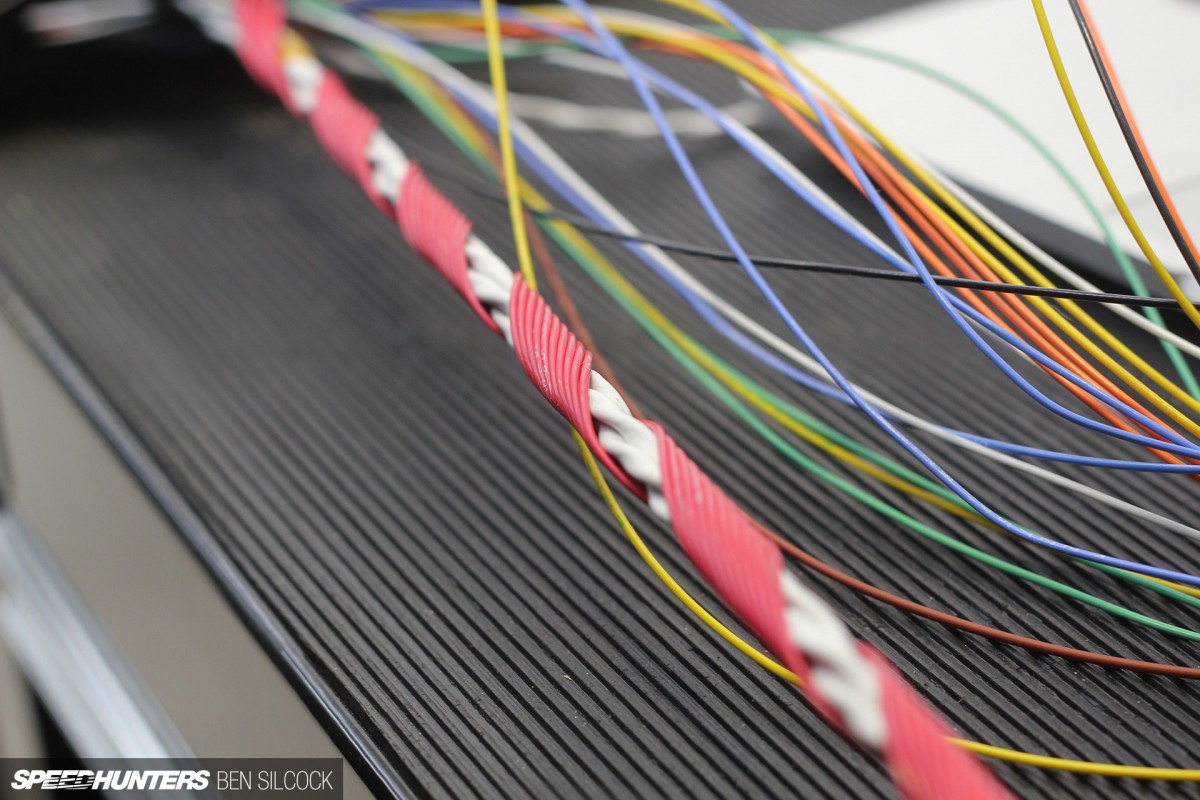

With concentric twisting there are different layers and direction of the twist of the wires alternates with each layer. With concentric twisting there are different layers and direction of the twist of the wires alternates with each layer.

Twisted Sheilded Wires Concentric Twisted High Performance

Concentric twisting wiring harness. This is a motorsports race spec technique and is not an aerospace standard where weight is critical. Know your wiring harness loom types sleeving duration. When you have a lot of wires in a loom it can be challenging to run them all in a neat fashion and keep flexibility in the loom once its shrunk with heat shrink. Concentric twisting refers to the way in which the different layers of wire in the harness are laid up. When you have a lot of wires in a loom it can be challenging to run them in all in a neat fashion and keep flexibility in the loom once its shrunk with heat shrink. When you have a lot of wires in a loom it can be challenging to run them in all in a neat fashion and keep flexibility in the loom once its shrunk with heat shrink.

The concentric twisting technique creates a wiring harness with a very small cross sectional area as well as a harness that offers great flexibility. Mil spec wiring loom high performance academy high performance academy. 22759 mil spec wires are twisted internally for the same reason. Concentric twisting refers to the way in which the different layers of wire in the harness are laid up. Concentric twisting refers to the way in which the different layers of wire in the harness are laid up. A properly twisted harness can look like a garden hose showing zero lumps or imperfect spots.

Why you would concentric twist a wiring harness if youve every searched motorsport wiring on the web you would have come across the term concentric twisting. Even though the term is used a lot there isnt much information on how it is constructed or even why you would construct a wiring harness in this way. What is concentric twisting. Concentric twist is a technique in which the wires are laid in opposing twisted directions giving max flexibility and minimum size to the harness bundle. Concentric twisting adds flexibilty to the harness were routing and possible removal are involved.