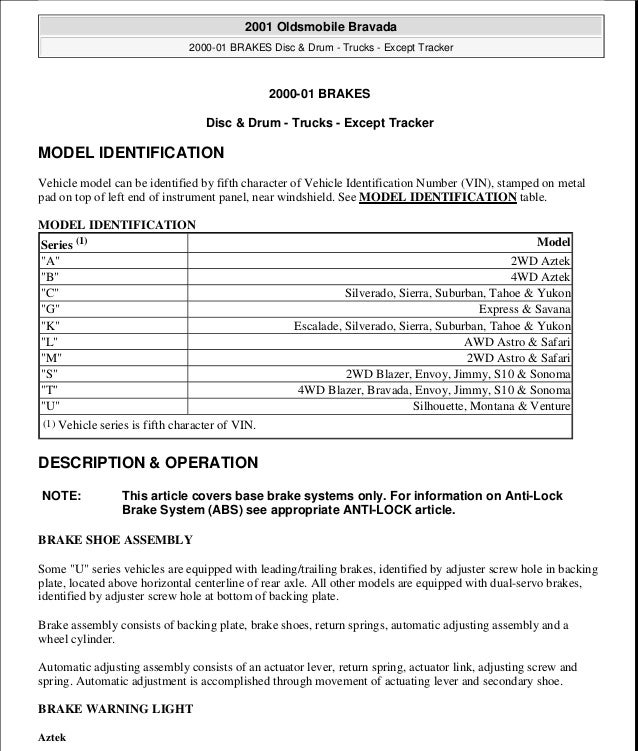

The easiest thread identification method is to use a thread id gauge such as brakequip thread id kit part bq2100. 0 select a store to see pricing availability.

Hydraulic Fitting Thread Chart Hydraulics Direct

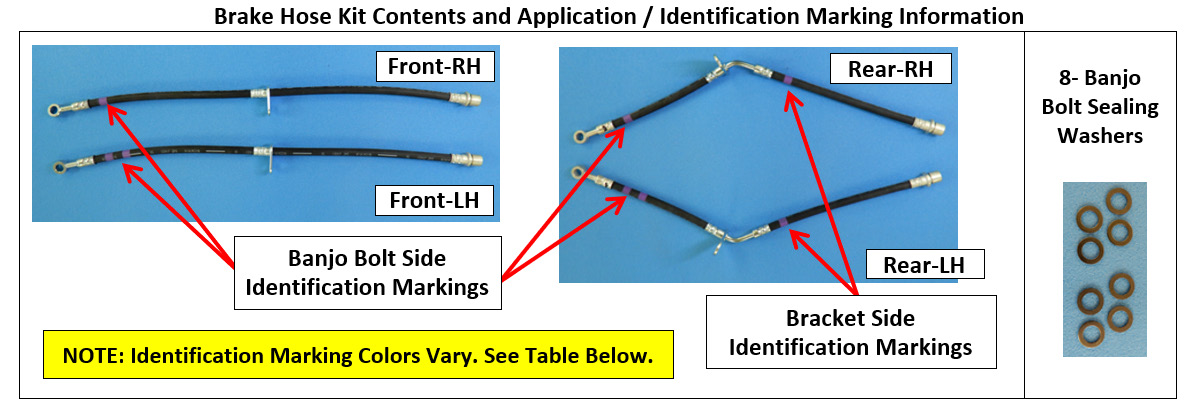

Brake line fitting identification. Search for a store. Identify the end configurations. Diniso bubble flare if the end of the tubing looks like a button and the back side angle of the flare is 90 degrees than it is the din flare. Alternatively you can take an unknown male or female part and try to screw it together with a part you already know the size of if it fits you now know the size of both. If your brake line looks like a tiny funnel going into the id of the tubing and the back side of the flare is at a 45 degree angle then it is the sae flare. Brake line fittings end configurations.

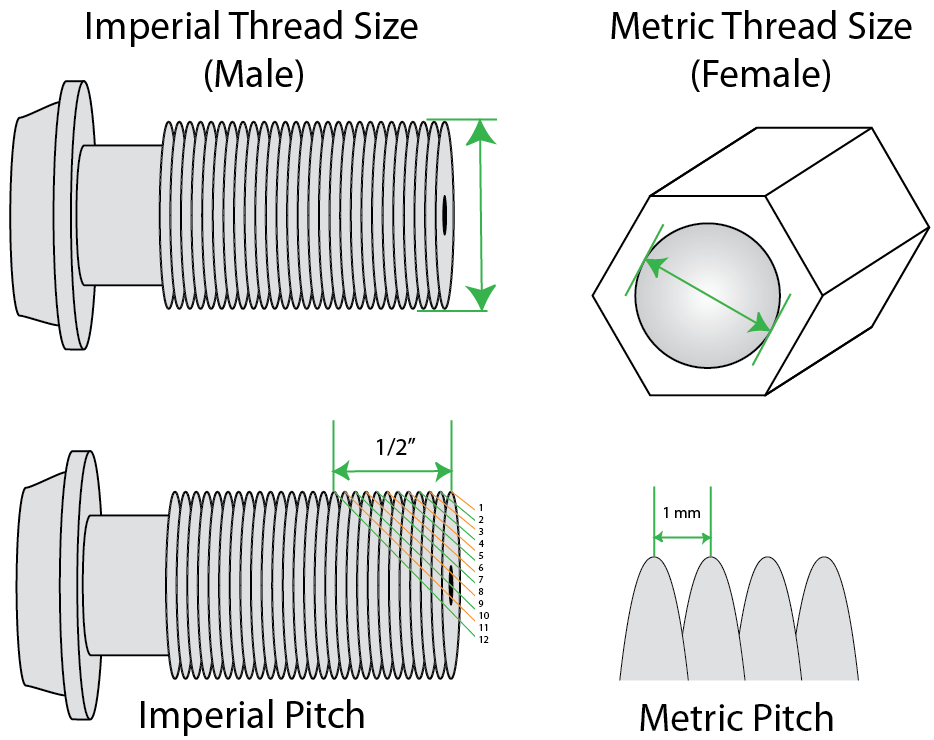

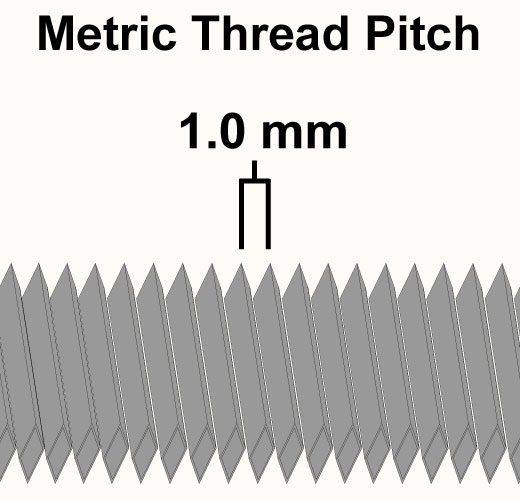

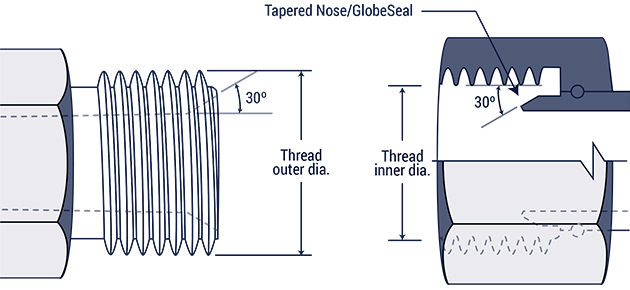

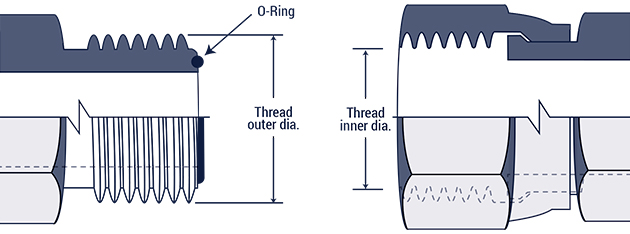

Manufacturers use identifiers such as asme b11 and iso 261 to classify the main thread characteristics. Identify the fittings group and type. Dont be misled by other brands that claim performance but buy all their products overseas. On rare occasions we come across a pipe thread but typically brake hose fittings involve a flare. Because connectors and ports have many applications in fluid piping systems you need to correctly identify them before adding or replacing them on a tube or hose in your specific application. Brake line thread identification.

Double inverted flare on the left bubble flare on the right. 316 inch tubing is one of the most common sizes used in brake systems which makes use of a 38 24 inverted flare nut like part number 91031820. 100 of our hose is made in the usa and all of our fittings and adapters are distributed from our warehouse in van wert oh. Pitch angle diameter and form. Hydraulic brake fitting adapters are used in a wide range of applications. Identifying your brake line fittings consists of three steps.

The soft line end is the male end. The hard line also has the nut that applies force necessary to seal the junction. Installation instructions cutting to length determine the length of the brake tube required using stiff wire solder tape measure or the old brake lines as a pattern. Aeroquip is the professionals choice and is the only company that manufacturers their own hose and fittings. On the right is a 37 single flared line with a tube sleeve and coupler that allows you to adapt to an fittings. With appropriate standard fittings and only up to recommended working pressure as indicated by the chart below.

They connect brake lines to the different diameter ports in a dual master cylinder combine various types of fittingsuch. Cut to the required length using a tube cutter. Brake adapter fittings sae. No rating value for american grease stick various various brake line fitting. In a typical brake line application the hard line end of the union is the female end the brake pipe itself is expanded around the center. There are three types of flares on brake hose fittings.

Identify the thread sizes. When autocomplete results are available use up and down arrows to review and enter to select.