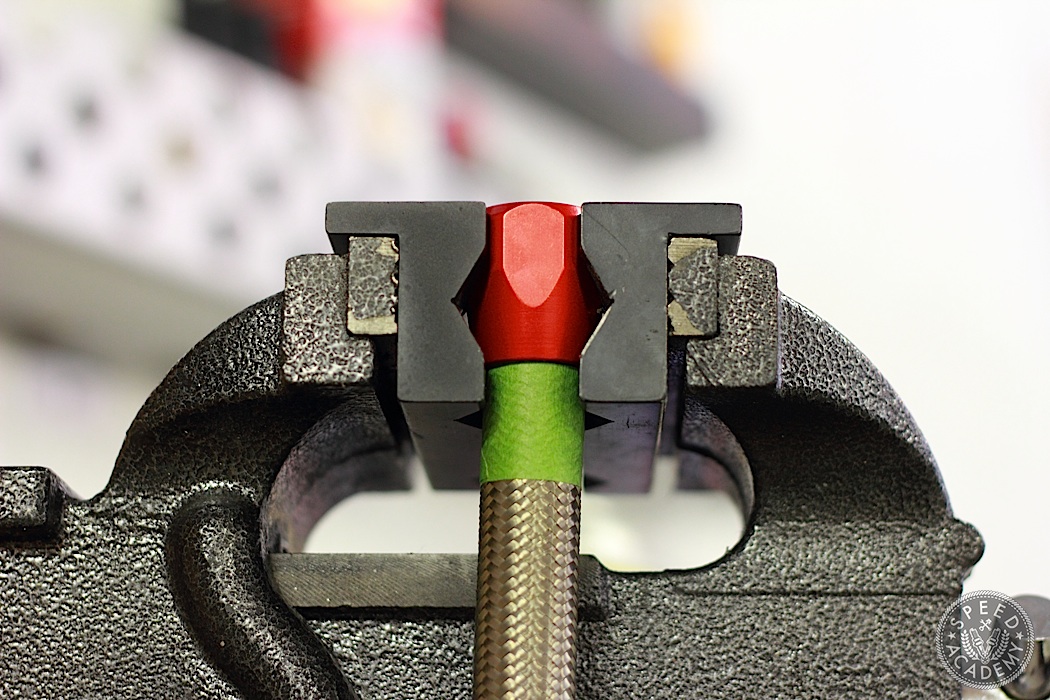

If the tubing is not perfect you can have issues with the compression fittings. Braided nylon hoses have an inner stainless steel braid covered by an outer nylon mesh to prevent this abrasion.

10 An An10 Nylon Braided Stainless Steel Fuel Line Hose Pipe

Braided nylon vs stainless steel fuel line. Braided lines are stiffer than rubber lines and are more durable. Found a site that wants 450 550 for hard lines with a corvette filter and compression fittings. You could also purchase braided hose to fit specific applications. This stuff has a history of failing and fuel leaks are not something to mess with. These types of hoses are typically used with crimp or reusable type an fittings. The nylon mesh however can get dirty and gunked up with contaminates.

I am not a big fan of the compression fittings. It bears the sae 30r5 rating and can withstand temperatures of 40 to 212 degrees. When a bent filler neck hose is necessary wire inserted fuel hose is also offered. Under no circumstances should you use the run of the mill rubber braided hose for fuel line. I read nhra requires braided steel lines ran along the frame rails. Push lock fitting use hoses with smooth outer skins over braided mesh.

I think i spent just 200 for my ls1 braided steel rubber lines with russell fittings and the corvette filter. I am making a set of 6 an lines for my transmission cooler. Braided hose provides better heat dissipation and better flow which is important when choosing performance car parts. Braided nylon vs braided stainless steel december 26th 2013 1100 pm. I went with teflon rubber for my fuel line both are stainless. Add the proper hose ends to the tubing if you buy a roll of it.

Anyone have any opinions on either of these. Working pressure is not relevant but wire inserted hose can withstand 50 85 psi depending on diameter. The nylon is a bit more per foot but it supposedly easier to make and i like the look a bit better. This was due to reformulated fuel with 10 percent ethanol attacking the rubber line dying it out and causing a massive leak when we turned the fuel pump was turned on. Special an type fittings are often necessary with steel braided fuel line. We had first hand experience with a budget stainless steel braided hose that dramatically failed within four months of installation on our drag race chevelle test car.